With the experience from 1974, we are at your service as ANKARA BRONZE. Ali Asker KADIOĞLU is the founder of our company, which is specialised in its field with the knowledge we have, different casting methods and pioneering technology, and honesty is our basic principle.

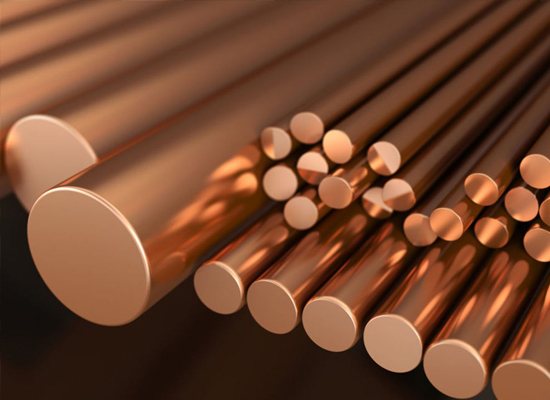

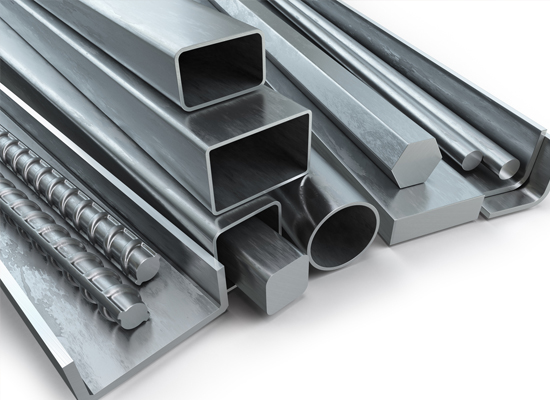

With its knowledge and expertise in different casting methods, we are able to cast Bronze, Aluminium, Brass and other special copper alloys in different sizes. Some of the alloys we cast;

Tin Bronze / Aluminium Bronze / Manganese Bronze / Silicon Bronze / Leaded Tin Bronze / High Leaded Tin Bronze / Nickel Tin Bronze and Brasses, Aluminums, Special Copper Alloys.

You can fill out the form below to reach Ankara Bronz instantly and get information about us.